Smart power sources are an extensive and very interesting area. We will gladly share the knowledge and experience we have acquired during the many years of our business. Read our articles to find out more. News and industry events will be included here.

News

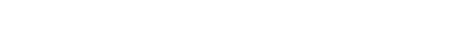

The Seven Passivation Pitfalls

news, 01 September, 2023

Primary Lithium Batteries

Lithium cells are by far the best power source for modern measuring devices, IoT and professional electronics. Properly selected cells ensure stable voltage, the longest life and reliability for many years of operation.

Wamtechnik Sp. z o. o. offers its customers products from the world’s best suppliers of lithium technology cells, such as SAFT France, Panasonic Japan, Maxell Japan, and others.

Selection of a lithium cell for a given device is crucial.

Operating profile of the device, both current-voltage, as well as the working environment, especially the exact temperature profile, should be carefully analyzed.

Compromise at this stage of power system development can have significant and, unfortunately, often very negative consequences for later operation, life and stability of the power supply.

Wamtechnik supports customers in such selection. With the support of mathematical modeling of the operation of cells offered by the best manufacturers, the selection guarantees reliability for many years of operation, even up to 15, 20 or even 25 years of operation in very different conditions.

Lithium Thionyl Chloride batteries are a common choice for IoT developers.

The chemistry offers a high operating voltage that is stable during most of the application’s lifetime, a high pulse capability, and the highest energy density among primary lithium chemistries. It can operate over a wide temperature range, has proven to be a reliable and long-life solution, and is also one of the cheapest options.

Those features make it a favorite choice for building smart devices.

Passivation is a surface protecting reaction which occurs spontaneously in all lithium batteries based on a liquid cathode, and plays a major role in many of these beneficial characteristics. However, when not well managed, passivation can adversely affect the operation of the application.

In this article we will explore the most common passivation pitfalls that our application engineers run into when receiving new application design submissions. Most importantly, we’ll discuss what you can do to avoid these mistakes.

What is passivation?

Passivation is a surface reaction that occurs spontaneously on the lithium metal surface in all primary Lithium batteries with liquid cathode material such as Li-SO2, Li-SOCl2 and Li-SO2Cl2. A film of lithium chloride (LiCl) quickly forms on the lithium metal anode surface, and this solid protecting film is called the passivation layer, that prevents direct contact between the anode (Li) and the cathode (SO2, SOCl2 and SO2Cl2).

Put simply, it prevents the battery to be in permanent internal short circuit and discharging of its own accord. That’s why it enables liquid cathode-based cells to have a long shelf life.

The passivation layer is electronically insulating, which may have some consequences for battery operation. The internal resistance of the cell is enhanced by the passivation layer, which can cause low voltage readings at startup (inferior to milliseconds range).

This initial voltage delay is quickly followed by a depassivation stage, during which transport of lithium ions by diffusion through the pores of the passivation layer becomes predominant over initial resistance. After this stage, cell voltage recovers to its nominal value under the given load or current applied. The passivation restarts after each current drain interruption.

Passivation is influenced by several factors that will effect the length and depth of the voltage delay such as its electrochemistry, the temperature in the field or the storage duration. The passivation layer builds up over time, and as a consequence, becomes thicker as storage time is extended.

A passivation issue therefore further impacts the voltage response after a few months or years in the field. Voltage delay caused by lithium passivation is sometimes underestimated by IoT developers who see their application ‘not behaving like it should’.

Let’s explore a few of the most common pitfalls and what can be done to avoid them

The Seven Passivation Pitfalls

https://www.youtube.com/watch?v=9838WfA8xJA&ab_channel=Saft

- Trying to reduce your consumption at all costs

If optimizing your device’s consumption in order to extend its lifetime is your primary goal, be careful not to lower your power consumption so much as to prevent the passivation layer breaking during the current connection. If the main energy consumption current is too low, ions from peak communication current won’t be able to flow through the passivation, which will be too thick, causing the voltage to drop below the cut off voltage and so, a loss of data transmission.

What to do

Find a good trade-off between the application’s lifetime and its discharge rate.

The current load must ideally allow for a rapid and efficient depassivation whilst offering the longest possible battery lifetime. If your application requires high current pulses, the initial voltage drop could also lead to a premature end of life. In this case, adding a capacitor to your battery is also an option: the capacitor will store the energy and release it when necessary, permitting a smoother depassivation of the battery.

- Not taking into account the field temperature of your application

Temperature has a significant impact on the evolution of the passivation layer. The higher the temperature, the faster the growth of the passivation layer, and the larger the LiCl crystals formed. Conversely, at cold temperatures, the electrolyte viscosity is higher which in turn slows electrochemical and diffusion reactions. The effect of passivation would likely be more visible, especially under high current draw.

What to do

Give some consideration as to where your application will be stored and deployed and which temperatures it is likely to be exposed to. Our application engineers can help you choose the right battery chemistry or adapt your device according to your power needs.

- Overlooking the application’s minimal cut-off voltage

Passivation can induce low voltage readings at current startup. As a result, applications featuring high cut off voltage are more prone to suffer from voltage delay. Voltage recordings below cut-off would likely trigger a “low battery” warning signal, or worse the current charge could be insufficient to break the passivation layer. This would mean that the cell voltage may never be able to recover to nominal values, which in turn could result in a loss of data to be transmitted or a reset of the device.

What to do

Lower the cut-off voltage for each of the application’s components as much as you can whilst being mindful of the current consumption. Since the power of the battery is the product of voltage and current, reducing a device’s operational voltage will enhance current consumption for the battery. The key to success is to find the right trade-off between the application’s lifetime and its discharge rate.

- Choosing a battery that is bigger than necessary

Some people think that a bigger battery will deliver current over a longer period of time. This is partly true. However, for a given average current a bigger battery will be more prone to passivation than a smaller one because current density referring to electrode overall surface area is comparatively lower. As explained above, a current that is too weak doesn’t allow for depassivation. In effect, the device could very well not start at all and the battery energy would be wasted.

What to do

Identify the battery construction and size that match your application’s lifetime and power needs – and ask our experts to help to choose what’s best for your device.

- Not considering the specific pulse requirements in the discharge profile of your application

Two aspects must be considered to evaluate the passivations risk: the maximum peak current value and the pulses frequency. High pulses applications might be disrupted by passivation: pulses are likely to perturb the crystals of the layer. More active materials will be needed to rebuild the layer after the current’s pulse. Those perturbations of the layer put a strain on the passivation’s effects and so voltage drops and voltage delays during the pulse are to be expected. Applications featuring long pauses between pulses have more chance of being disrupted by passivation too, as the passivation has more time to rebuild and grow between two pulses.

- An application with high pulses with low frequency will have a high risk of passivation and disruption of service.

- An application with high pulses with high frequency will have a lower risk of passivation but a high average current, and therefore a high-energy consumption.

- An application with low pulses and high frequency shouldn’t have an issue with passivation.

- An application with low pulses and low frequency will have a moderate risk of passivation, depending on the exact values and other environmental conditions.

What to do

Again, it’s all about anticipating your application’s power requirement to find the right trade-off between your consumption profile and the energy load. If your application requires a high and / or frequent pulse, you might need to design a bespoke energy solution that will offer a sufficient lifetime for your application. If you have a low frequency pulse, then you should evaluate the passivation risk with your battery manufacturer.

- Taking the information indicated on the datasheet at face value

No matter how much we would like to, it is impossible to provide all technical information useful for any possible field application of a given battery product within a single datasheet. The pulse levels and current information indicated on a datasheet are fixed values that don’t consider your application’s specificities.

What to do

You could talk to our engineers who will be able to analyze your application’s specific power prerequisites and constraints to recommend the best option to match your needs.

Also, you can test your application in conditions that are as close as possible to reality (or test the battery by stocking it in a warm environment to make it age prematurely before testing the pulse). The values won’t be exact but you will be able to evaluate the overall field behavior of the battery.

- Believing that a test at ambient temperature is fully representative of the overall field behavior of your application

Test, test, test – but don’t think that a test at ambient temperature and over a short period of time can replace a real life test over several years. Passivation is a natural phenomenon that evolves over the years and depends on the various temperatures that the application is exposed to. Unfortunately, its aging can’t be modeled or accelerated which leaves too many unknowns for an accelerated test to be 100% conclusive.

What to do

Nothing can replace a real world test of your application.

But to evaluate the likely effect of passivation in your device, it’s worth leaning on the experts. Our application engineers have seen, tested and recommended battery solutions for many applications and can help you select the right batteries.

Source: saft.com